Water Based Waterproofing Acrylic Paint For House & Building Decoration

Product Parameter

| Packaging specification | 25kg /bucket |

| Model NO. | BPB-7045 |

| Brand | Popar |

| Level | Finish coat |

| Main raw material | Acrylic |

| Drying method | Air drying |

| Packaging mode | Plastic bucket |

| Application | Suitable for waterproofing outdoor ceilings, swimming pools ,basement .indoor kitchens and bathrooms |

| Acceptance | OEM/ODM, Trade, Wholesale, Regional Agency |

| Payment method | T/T, L/C, PayPal |

| Certificate | ISO14001, ISO9001,French VOC a+ certification |

| Physical state | Liquid |

| Country of origin | Made in China |

| Production capacity | 250000 Ton/Year |

| Application method | Roller or brush coating |

| MOQ | ≥20000.00 CYN (Min. Order) |

| pH value | 8-10 |

| Solid content | 50% |

| Viscosity | 1300Pa.s |

| Stroge life | 2 years |

| Color | White |

| HS Code | 320990100 |

Product Description

It is suitable for waterproofing outdoor ceilings, swimming pools, indoor kitchens and toilets.

Product Features

Strong adhesion, good flexibility.

Excellent waterproof performance and Easy to construct.

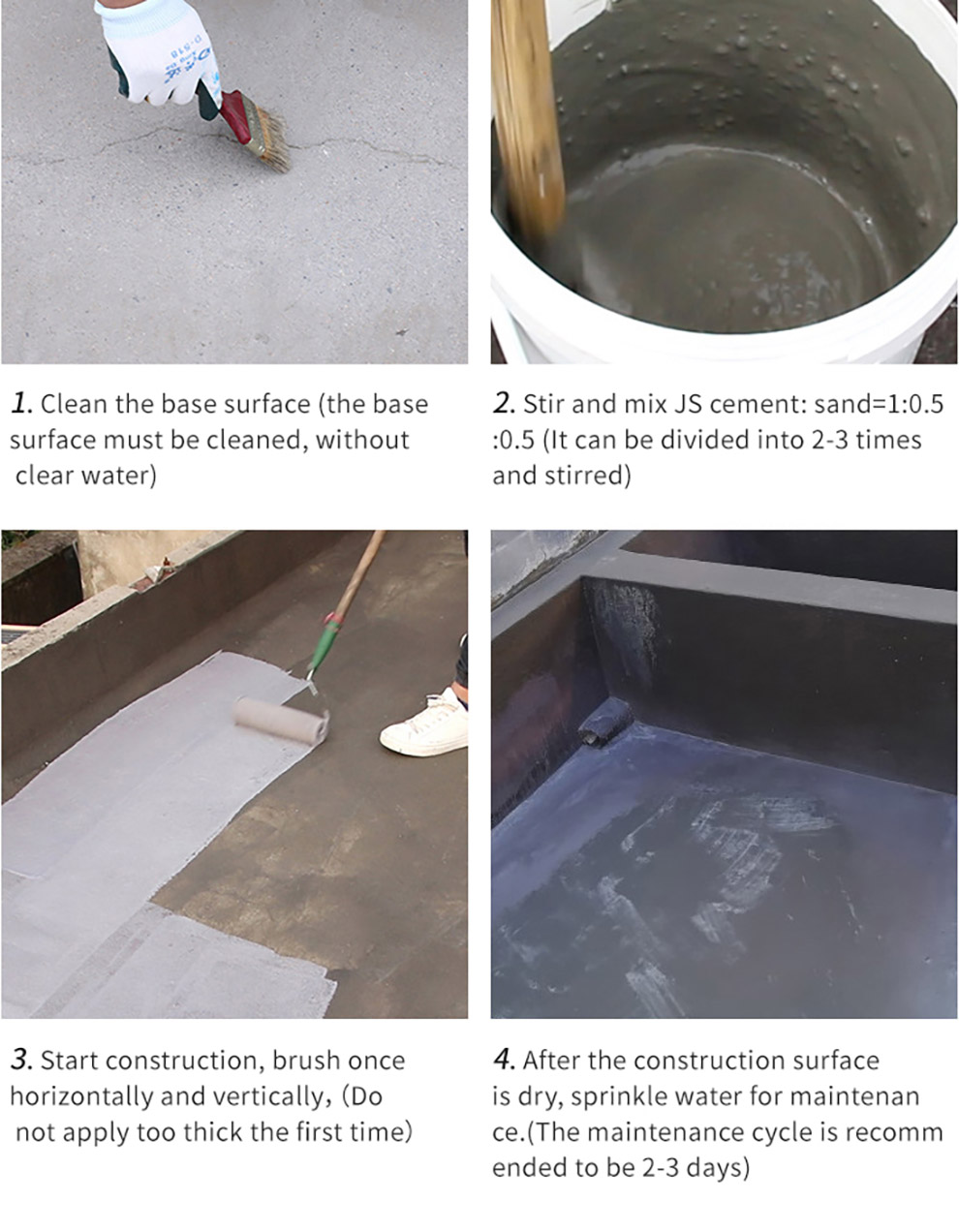

Method of Application

When the coating film of the waterproof layer is 1.0 mm thick, the usage is about 1.7 ~ 1.9 kg/m2. (Actual usage depends on the substrate condition and coating thickness.)

The coating film thickness of the waterproof layer shall not be less than 1.5mm, and the thickness of the vertical plane shall not be less than 1.2mm.

The product mix ratio is liquid: cement = 1:1 (mass ratio).

Substrate treatment → additional waterproof layer in details → coating for large-area waterproof layer → quality inspection and acceptance → application of protective and isolation layers

The normal application temperature is 5 ℃ ~ 35 ℃. Application is not allowed in rainy weather.

Substrate treatment: The substrate should be flat, solid, clean, and free of visible water, ash and oil stains. Internal and external corners and tube roots should be subject to arc treatment.

Coating ratio: Refer to the product certificate for the mixture ratio. First, add the liquid material into a mixing bucket. Then, slowly add the cement material in the process of mechanical mixing, and mix evenly. The prepared coating should be used up within 2 hours.

Additional waterproof layer in details: An additional layer should be made for internal and external corners, pipe roots, drainage outlets and other detail nodes, which are to be coated 2-3 times, and matrix reinforcement material shall be sandwiched to make the waterproof coating fully permeate the matrix layer, without wrinkle and edge warping.

Coating for large-area waterproof layer: For large waterproof layers, it is proper to coat the facade first and then the planes, with 2-3 courses of coating applied. However, the next course can only start after the previous coating is dry, and the direction of coating should be vertical to that of the preceding coating.

Application of protective and isolation layers: In a humid environment, the drying of the product will become slow, and the drying time should be appropriately extended. After the waterproof layer is completely dried, the closed water test should be carried out. After acceptance inspection, the protective and isolation layers should be applied according to the design requirements.

Transportation & Storage

This product is a non-flammable and non-explosive material and can be transported as general goods. During transportation, it is necessary to prevent rain, sun exposure, freezing, extrusion and collision, and keep the package intact.

Store the product in a cool and dry place at 5 ℃ to 35 ℃, and avoid sun exposure, freezing, extrusion and collision.

Under normal transportation and storage conditions, the product lasts for 24 months.

Points for Attention

After the coating is mixed according to the specified ratio, please use it up within 2 hours.

It will take 2~3 days for the coating film to dry completely, and the drying time should be appropriately prolonged in a humid environment.

After the coating film is completely dry, closed water test can be carried out. After acceptance inspection, the protective and isolation layers shall be applied according to the design requirements.

Product construction steps

Product Display