Water Based Super Weather Resistance with Acrylic Paint Coating for Exterior Wall

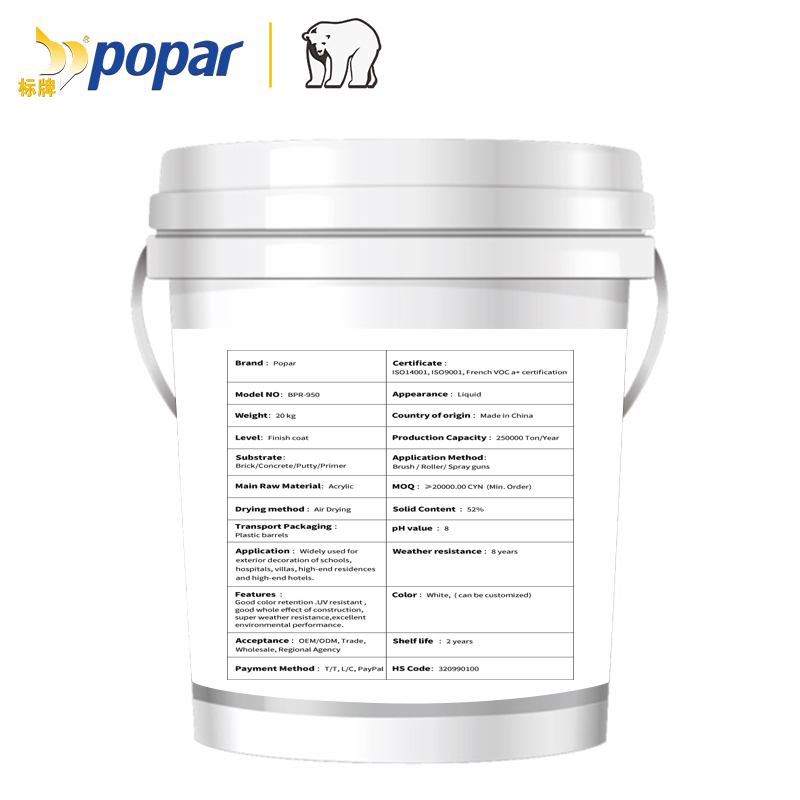

Product Parameter

| Packaging specification | 20 kg /bucket |

| Model NO. | BPR-950 |

| Brand | Popar |

| Level | Finish coat |

| Substrate | Brick/Concrete/Putty/Primer |

| Main raw material | Acrylic |

| Drying method | Air drying |

| Packaging mode | Plastic bucket |

| Application | Widely used for exterior decoration of schools, hospitals, villas, high-end residences and high-end hotels. |

| Features | Good color retention. UV resistant, good whole effect of construction, super weather resistance, excellent environmental performance |

| Acceptance | OEM/ODM, Trade, Wholesale, Regional Agency |

| Payment method | T/T, L/C, PayPal |

| Certificate | ISO14001, ISO9001, French VOC a+ certification |

| Physical state | Liquid |

| Country of origin | Made in China |

| Production capacity | 250000 Ton/Year |

| Application method | Brush / Roller / Spray guns |

| MOQ | ≥20000.00 CYN (Min. Order) |

| Solid content | 52% |

| pH value | 8 |

| Weather resistance | 8 years |

| Shelf life | 2 years |

| Color | White, ( can be customized) |

| HS Code | 320990100 |

Product Description

Exterior wall paint selects high-quality raw materials, does not add fragrance, and adopts advanced production technology to make the home natural, pure, environmentally friendly and comfortable.

Product Application

Product Features & Benefits

Strong bacterial resistance.UV resistant, good color retention, good whole effect of construction,super weather resistance, excellent environmental performance.

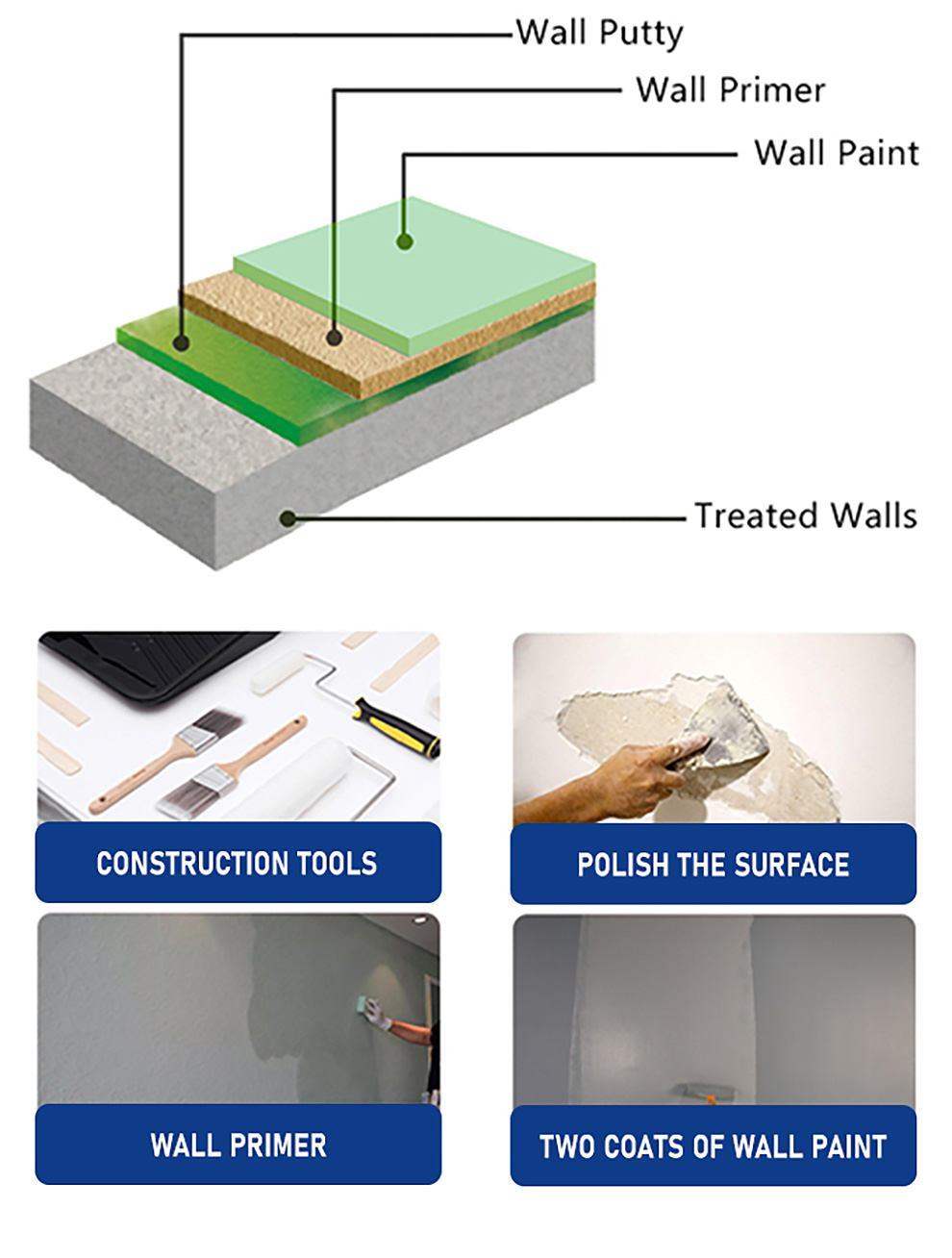

Direction For Use

Application instructions: The surface must be clean, dry, neutral, flat, and free of floating ash, oil stains and foreign matters. Water-leaking positions must undergo waterproof treatment. Before coating, the surface should be polished and leveled to ensure that the surface humidity of the pre-coated substrate is <10% and the pH value is<10. The coating surface effect depends on substrate evenness.

Application conditions: Wall temperature ≥ 5 ℃, humidity ≤ 85%, and good ventilation.

Application methods: Brush coating, roller coating and spraying.

Dilution ratio: Dilute with a proper amount of clear water (to the extent of being suitable for pasting) Water to paint ratio 0.2:1 . Remember mixing well before using .

Theoretical paint consumption: 4-5㎡/Kg (two times of roller coating); 2-3㎡/Kg (two times of spraying). (The actual amount varies slightly due to the roughness and looseness of the base layer).

Recoating time: 30-60 minutes after surface drying, 2 hours after hard drying, and recoating interval is 2-3 hours (which may be duly extended under low-temperature and high-humidity conditions).

Maintenance time: 7 days/25℃, which may be duly extended under low-temperature and high-humidity conditions to obtain a solid film effect. In the process of paint film maintenance and daily use, it is suggested that doors and windows should be closed for dehumidification in high humidity weather (such as Wet Spring and Plum Rain).

Tool Cleaning: After or between applications, please clean the tools with clean water in time in order to prolong tool life. The packaging bucket can be recycled after cleaning, and packaging waste may be recycled for reuse.

Substrate Treatment

1. New wall: Thoroughly remove surface dust, oil stains, loose plaster, etc., and repair any holes to ensure that the wall surface is clean, dry and even.

2. Re-painting wall: Thoroughly remove the original paint film and putty layer, clean surface dust, and level, polish, clean and thoroughly dry the surface, so as to avoid problems left over from the old wall (odor, mildew, etc.) affecting the application effect.

*Before coating, the substrate should be checked; coating can only start after the substrate has passed acceptance inspection.

Precautions

1. Please work in a well-ventilated environment, and wear a protective mask when polishing the wall.

2. During construction, please configure necessary protective and labor protection products according to local operating regulations, such as protective glasses, gloves and professional spraying clothing.

3. If it gets into eyes accidentally, please rinse well with plenty of water and seek medical treatment immediately.

4. Do not pour the remaining paint liquid into the sewer to avoid clogging. When disposing of paint waste, please comply with local environmental protection standards.

5. This product must be sealed and stored in a cool and dry place at 0-40°C. Please refer to the label for details on production date, batch number and shelf life.

Product construction steps

Product Display

Substrate Treatment

1. New wall: Thoroughly remove surface dust, oil stains, loose plaster, etc., and repair any holes to ensure that the wall surface is clean, dry and even.

2. Re-painting wall: Thoroughly remove the original paint film and putty layer, clean surface dust, and level, polish, clean and thoroughly dry the surface, so as to avoid problems left over from the old wall (odor, mildew, etc.) affecting the application effect.

*Before coating, the substrate should be checked; coating can only start after the substrate has passed acceptance inspection.

Precautions

1. Please work in a well-ventilated environment, and wear a protective mask when polishing the wall.

2. During construction, please configure necessary protective and labor protection products according to local operating regulations, such as protective glasses, gloves and professional spraying clothing.

3. If it gets into eyes accidentally, please rinse well with plenty of water and seek medical treatment immediately.

4. Do not pour the remaining paint liquid into the sewer to avoid clogging. When disposing of paint waste, please comply with local environmental protection standards.

5. This product must be sealed and stored in a cool and dry place at 0-40°C. Please refer to the label for details on production date, batch number and shelf life.