Poparpaint Water based Elastic Exterior Wall Paint

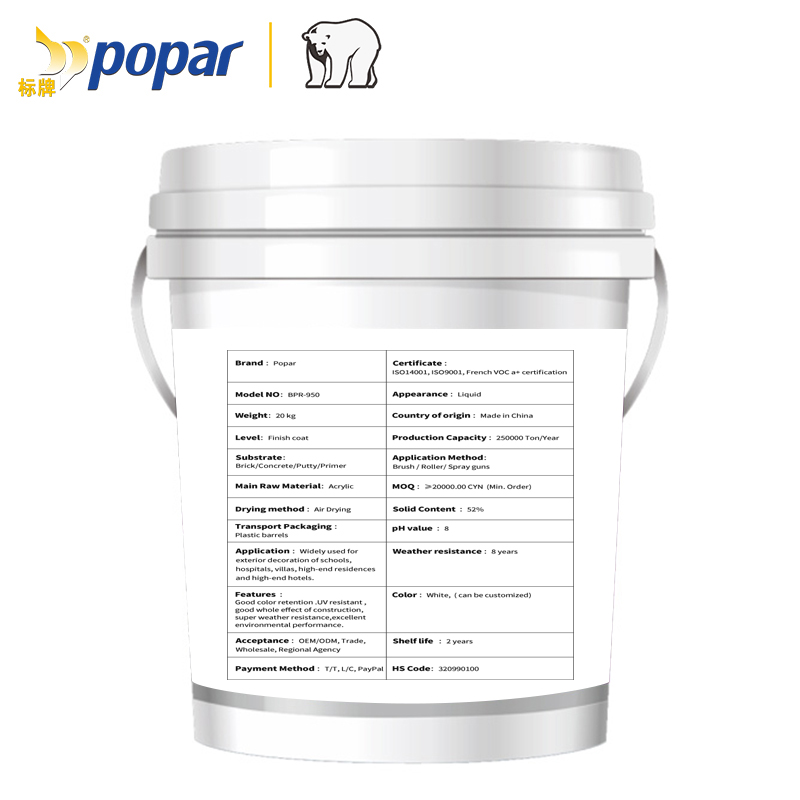

Product Parameter

| Ingredients | Water; Environmental protection emulsion based on water; Environmental protection pigment; Environmental protection additive |

| Viscosity | 113Pa.s |

| pH value | 8 |

| Weather resistance | Ten years |

| Theoretical coverage | 0.95 |

| Drying time | Surface dry for 30-60 minutes. |

| Repainting time | 2 hours (in wet weather or the temperature is too low, the time should be extended appropriately) |

| Solid content | 52% |

| Proportion | 1.3 |

| Brand No. | BPR-992 |

| Country of origin | Made in China |

| Physical state | white viscous liquid |

Product Application

It is suitable for the decorative coating application of exterior walls of luxury high-end villas, high-end residences, high-end hotels, and office spaces.

Product Features

Super elastic properties of paint film, effectively covering and preventing micro cracks

Excellent stain resistance. Mildew and resistance to algae. Excellent outdoor weatherability.

Instructions

Theoretical paint consumption (30μm dry film)

10㎡/L/layer (the actual amount varies slightly due to the roughness and porosity of the base layer).

Dilution

Diluting with water is not recommended.

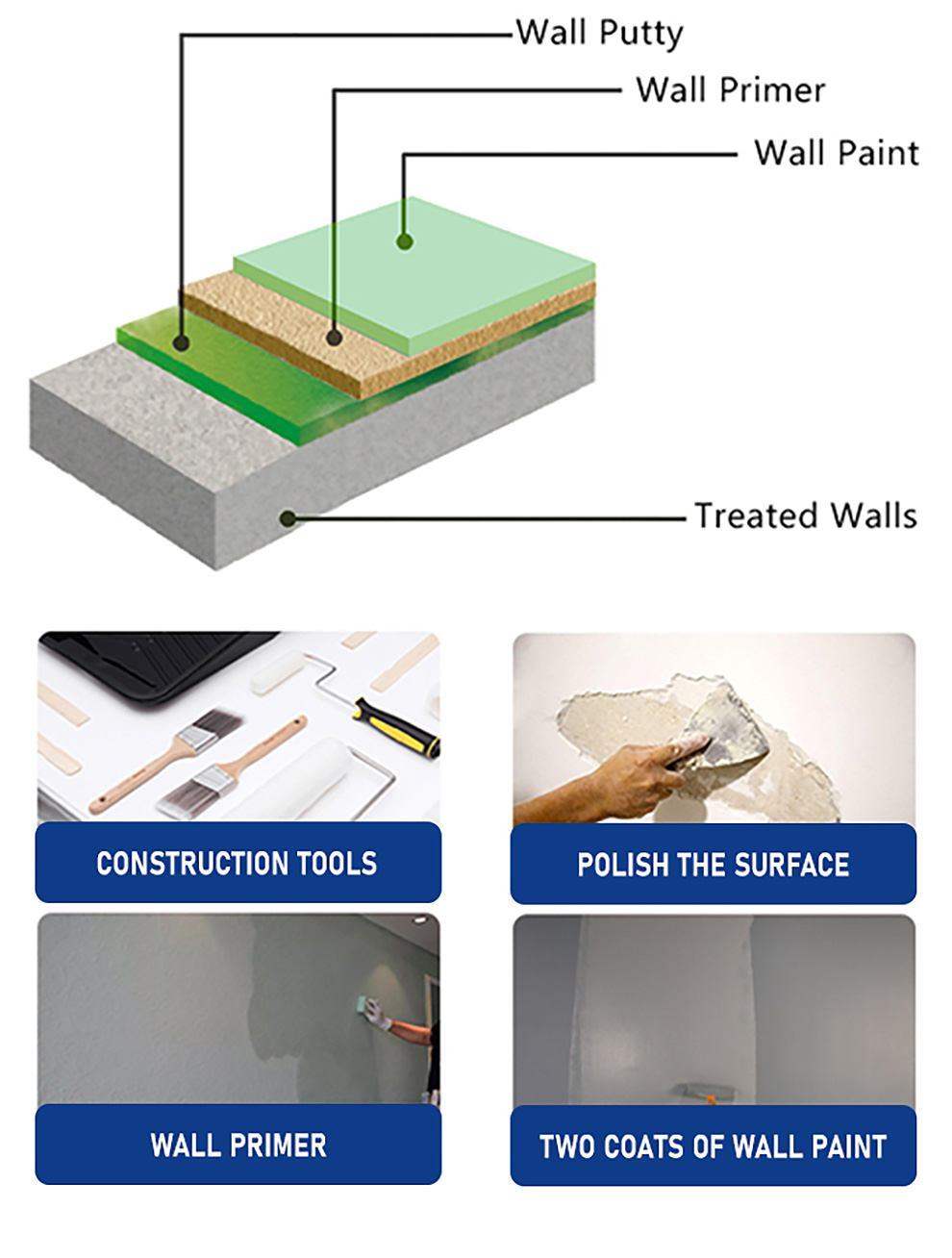

Coating system and coating times

♦ Clean the base: remove the residual slurry and unstable attachments on the wall, and use a spatula to shovel the wall, especially the corners of the window frame.

♦ Protection: Protect door and window frames, glass curtain walls, and finished and semi-finished products that do not require construction before construction to avoid pollution.

♦ Putty repair: This is the key to base treatment. At present, we often use waterproof exterior wall putty or flexible exterior wall putty.

♦ Sandpaper grinding: When sanding, it is mainly to polish the place where the putty is connected. When grinding, pay attention to the technique and follow the operating specification. Use water emery cloth for sandpaper, and use 80 mesh or 120 mesh water emery cloth for sanding the putty layer.

♦ Partial putty repair: After the base layer is dry, use putty to find unevenness, and the sand will be flat after drying. The finished putty should be stirred well before use. If the putty is too thick, you can add water to adjust it.

♦ Full scraping putty: Put the putty on the pallet, scrape it with a trowel or squeegee, first up and then down. Scrape and apply 2-3 times according to the condition of the base layer and decoration requirements, and the putty should not be too thick each time. After the putty is dry, it should be polished with sandpaper on time, and it should not be wavy or leave any grinding marks. After the putty is polished, sweep away the floating dust.

♦ Primer coating construction: use a roller or row of pens to evenly brush the primer once, be careful not to miss the brush, and don't brush too thick.

♦ Repair after painting the anti-alkali sealing primer: After the anti-alkali sealing primer is dry, some small cracks and other defects on the wall will be exposed due to the good permeability of the anti-alkali sealing primer. At this time, it can be repaired with acrylic putty. After drying and polishing, reapply the anti-alkali sealing primer to prevent the inconsistency of the absorption effect of the opposite paint due to the previous repair, thus affecting its final effect.

♦ Topcoat construction: After the topcoat is opened, stir evenly, then dilute and stir evenly according to the ratio required by the product manual. When color separation is required on the wall, first pop out the color separation line with a chalk line bag or ink fountain, and leave 1-2cm of space at the cross-color part when painting. One person first uses a roller brush to dip the paint evenly, and the other person then uses a row brush to flatten the paint marks and splashes (spraying construction method can also be used). The bottom and flow should be prevented. Each painted surface should be painted from the edge to the other side and should be finished in one pass to avoid seams. After the first coat is dry, apply a second coat of paint.

♦ Completion cleaning: After each construction, rollers and brushes should be cleaned, dried and hung in the designated position. Other tools and equipment, such as wires, lamps, ladders, etc., should be taken back in time after the construction is completed, and should not be placed randomly. Mechanical equipment should be cleaned and repaired on time. After the construction is completed, keep the construction site clean and hygienic, and the contaminated construction sites and equipment should be cleaned up on time. The plastic film or tape used to protect the wall should be cleaned before dismantling.

Application conditions

Please do not apply in wet or cold weather (the temperature is below 5°C and the relative degree is above 85%) or the expected coating effect will not be achieved.

Please use it in a well ventilated place. If you really need to work in a closed environment, you must install ventilation and use appropriate protective devices.

Maintenance time

7 days/25°C, low temperature (not lower than 5°C) should be extended appropriately to obtain the ideal paint film effect.

Powdered surface

1. Remove the powdered coating from the surface as much as possible, and level it again with putty.

2. After the putty is dry, smooth with fine sandpaper and remove powder.

Moldy surface

1. Shovel with a spatula and sand with sandpaper to remove mildew.

2. Brush 1 time with appropriate mold washing water, and wash it with clean water in time, and let it dry completely.

Tool Cleaning

Please use clean water to wash all utensils on time after stopping in the middle of painting and after painting.

Packaging specification

20KG

Storage method

Store in a cool and dry warehouse at 0°C-35°C, avoid rain and sun exposure, and strictly prevent frost. Avoid stacking too high.

Product construction steps

Product Display