Poparpaint All-purpose Sealing Primer for Exterior Walls (transparent color)

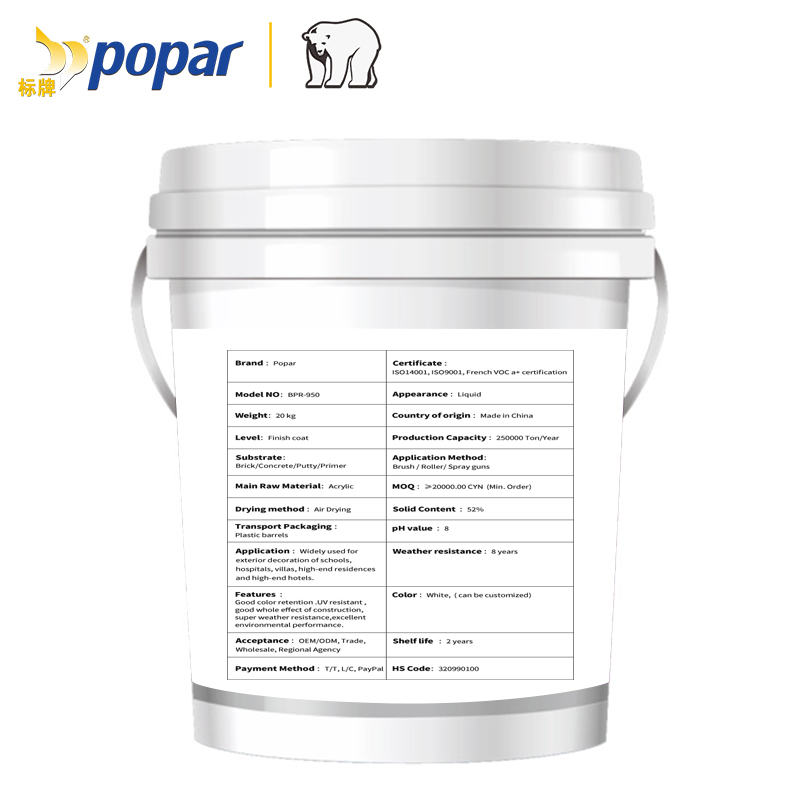

Product Parameter

| Ingredients | Water; Environmental protection emulsion based on water; Environmental protection additiv |

| Viscosity | 45Pa.s |

| pH value | 7.5 |

| Drying time | Surface dry 2 hours |

| Solid content | 25% |

| Proportion | 1.3 |

| Brand No. | BPR-9001 |

| Country of origin | Made in China |

| Physical state | white viscous liquid |

Product Application

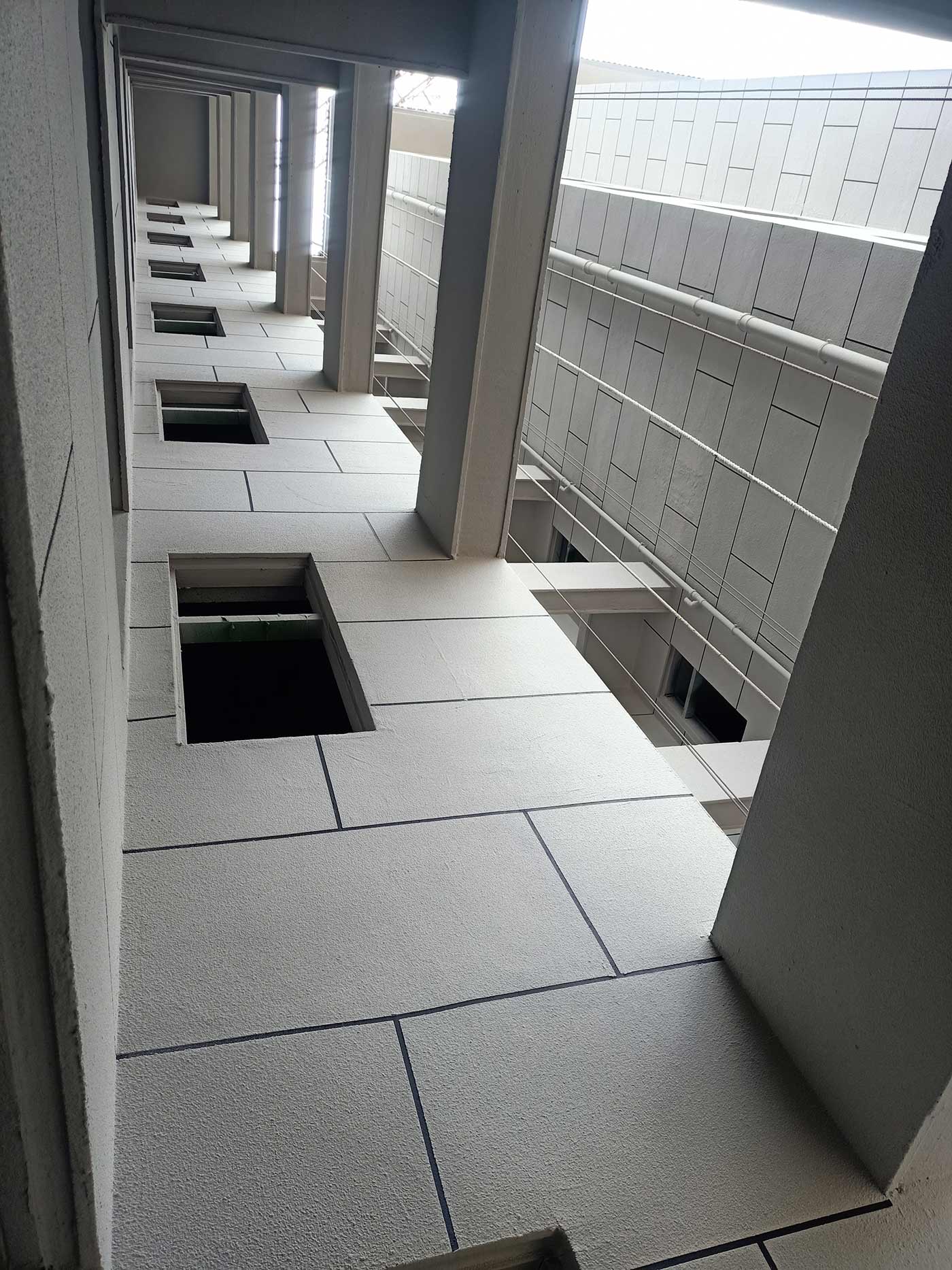

It is suitable for the decorative coating application of the exterior walls of luxury high-end villas, high-end residences, high-end hotels, and office spaces.

Product Features

1. Effectively penetrate the micropores of the wall to form a dense water-resistant, alkali-resistant and weather-resistant paint film.

2. Good sealing.

3. Excellent adhesion.

4. Effectively improve the fullness and gloss uniformity of the topcoat.

Product Instructions

Construction technology

The surface must be clean, dry, neutral, flat, free of floating dust, oil stains and sundries, the leaking part must be sealed, and the surface must be polished and smoothed before painting to ensure that the surface humidity of the pre-coated substrate is less than 10%, and the pH value is less than 10. The quality of the paint effect depends on the flatness of the base layer.

Application conditions

Please do not apply in wet or cold weather (the temperature is below 5°C and the relative degree is above 85%) or the expected coating effect will not be achieved.

Please use it in a well ventilated place. If you really need to work in a closed environment, you must install ventilation and use appropriate protective devices.

Tool cleaning

Please use clean water to wash all utensils on time after stopping in the middle of painting and after painting.

Theoretical paint consumption

10㎡/L/layer (the actual amount varies slightly due to the roughness and looseness of the base layer)

Packaging specification

20KG

Storage method

Store in a cool and dry warehouse at 0°C-35°C, avoid rain and sun exposure, and strictly prevent frost. Avoid stacking too high.

Instructions for Use

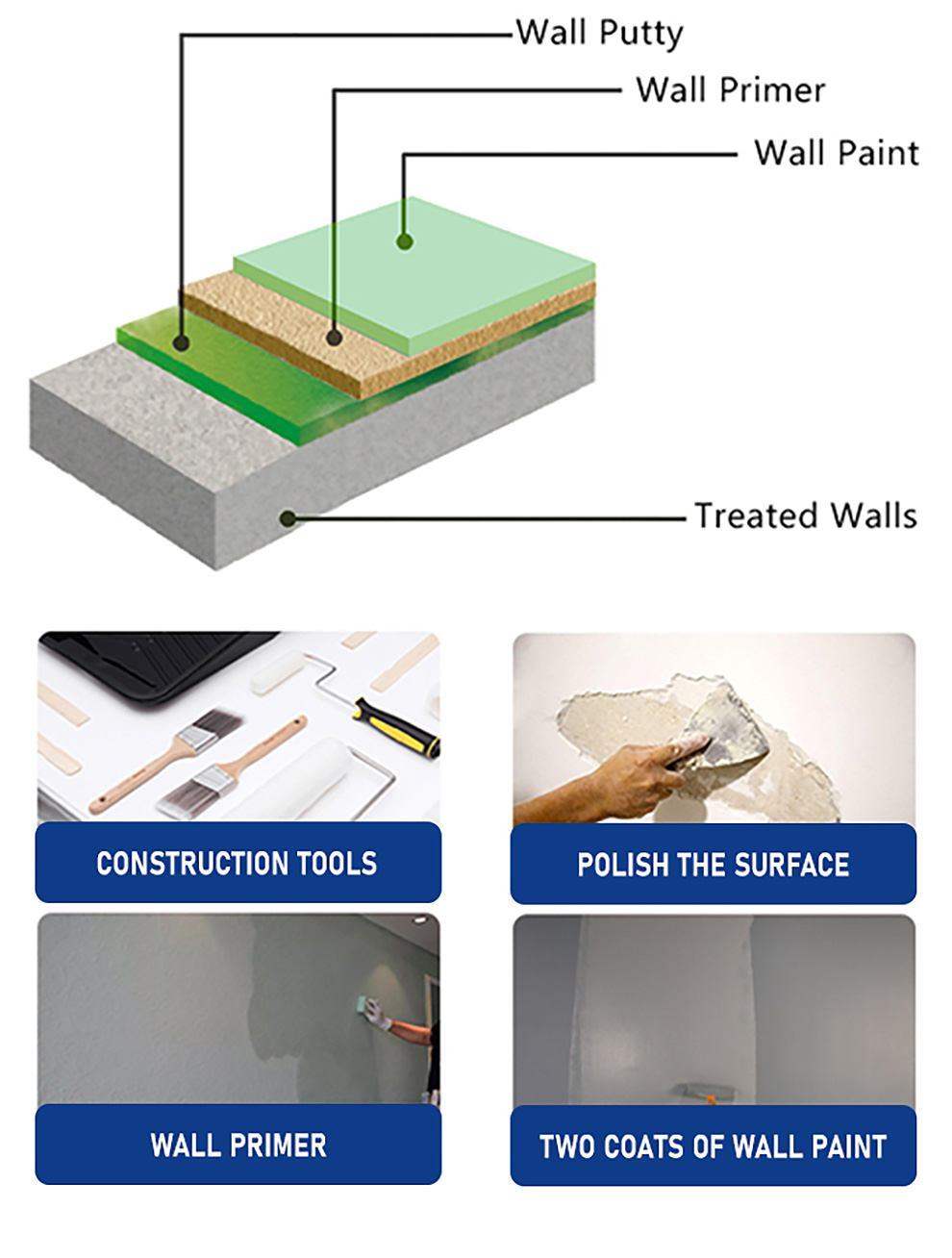

Substrate treatment

When building a new wall, remove surface dust, greasy and loose plaster, and if there are pores, repair it in time to ensure that the wall is clean, dry and smooth. First recoating the wall surface: eradicate the weak paint film on the old wall surface, remove the dust powder and impurities on the surface, flatten and polish it, clean it and dry it thoroughly.

Surface condition

The surface of the precoated substrate must be firm, dry, clean, smooth and free of loose matter.

Ensure that the surface humidity of the precoated substrate is less than 10% and the pH is less than 10.

Coating system and coating times

♦ Base treatment: check whether the wall surface is smooth, dry, free of dirt, hollowing, cracking, etc., and repair it with cement slurry or exterior wall putty if necessary.

♦ Construction primer: apply a layer of moisture-proof and alkali-resistant sealing primer on the base layer by spraying or rolling to enhance waterproof, moisture-proof effect and bonding strength.

♦ Separation line processing: If a grid pattern is required, use a ruler or a marking line to make a straight line mark, and cover and paste it with washi tape. Note that the horizontal line is pasted first and the vertical line is pasted later, and iron nails can be nailed to the joints.

♦ Spray real stone paint: Stir the real stone paint evenly, install it in a special spray gun, and spray it from top to bottom and from left to right. The thickness of spraying is about 2-3mm, and the number of times is two times. Pay attention to adjusting the nozzle diameter and distance to achieve the ideal spot size and convex and concave feel.

♦ Remove the mesh tape: Before the real stone paint is dry, carefully tear off the tape along the seam, and be careful not to affect the cut corners of the coating film. The removal sequence is to remove the horizontal lines first and then the vertical lines.

♦ Water-in-sand primer: Apply water-in-sand primer on the dried primer surface to make it cover evenly and wait for drying.

♦ Respray and repair: Check the construction surface in time, and repair parts such as through-bottom, missing spray, uneven color, and unclear lines until they meet the requirements.

♦ Grinding: After the real stone paint is completely dry and hardened, use 400-600 mesh abrasive cloth to polish the sharp-angled stone particles on the surface to increase the beauty of the crushed stone and reduce the damage of the sharp stone particles to the topcoat.

♦ Construction finish paint: Use an air pump to blow off the floating ash on the surface of the real stone paint, and then spray or roll the finish paint all over to improve the waterproof and stain resistance of the real stone paint. The finished paint can be sprayed twice with an interval of 2 hours.

♦ Demolition protection: After the construction of the topcoat is completed, check and accept all construction parts, and remove the protective facilities on doors, windows and other parts after confirming that they are correct.

Maintenance time

7 days/25°C, low temperature (not lower than 5°C) should be extended appropriately to obtain the ideal paint film effect.

Powdered surface

1. Remove the powdered coating from the surface as much as possible, and level it again with putty.

2. After the putty is dry, smooth with fine sandpaper and remove powder.

Moldy surface

1. Shovel with a spatula and sand with sandpaper to remove mildew.

2. Brush 1 time with appropriate mold washing water, and wash it with clean water in time, and let it dry completely.

Points to Attention

Construction and use suggestions

1. Carefully read the instructions for using this product before construction.

2. It is recommended to try it in a small area first, and if you have any questions, please consult on time before using it.

3. Avoid storage at low temperatures or exposure to sunlight.

4. Use according to product technical instructions.

Executive standard

The product complies with GB/T9755-2014 "Synthetic Resin Emulsion Exterior Wall Coatings"

Product construction steps

Product Display